Research project

B. Nano structure control in nitrides and oxides of iron for high functionality

1. Introduction

Iron is rich in natural resources and environmental benign. It has been widely used as

ferromagnetic as well as structural materials. Iron nitride,

Fe16N2, has

been expected to have the largest magnetic moment among the ferromagnetic materials. It will be

used in magnetic core, recording media and so on in high performance by controlling its magnetic

domain size. Difficulty in its preparation has been recently solved by nano-sized powder preparation.

Large magnetic coersivity of 20kOe was also recently reported on e-Fe2O3 fine powder in rod shape. Tunnel type magnetoresistance effect for magnetic sensor

application can be expected on granular materials where ferromagnetic fine particles are

dispersed in nonmagnetic matrix. The nano structure control in nitrides and oxides of

iron will bring us to a new era of magnetic materials.

2. Research results

(1) Fe16N2 fine powder prepared in low temperature nitridation and its magnetic properties

It was prepared by nitridation of iron oxide fine power in ammonia flow after the reduction

in hydrogen ammonia. Reproducibility was recently much improved by removing the residual

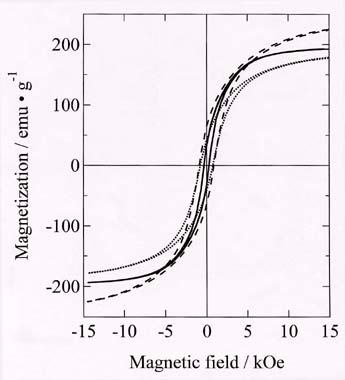

humidity in the reaction system. Its magnetic coersivity was about 0.9kOe and the magnetization

was saturated to 216emu/g in a magnetic field of 4T.

Fig. 3. Magnetic hysteresis loops for a-Fe starting powder (solid line), and products nitrided at 130oC for 50 hours (dotted line)

and 100 hours (broken line).

(2) Ferromagnetic granular thin films prepared by post annealing of sputter deposited iron based nitride

Nitrides of 3d transition metals thermally decompose releasing nitrogen at relatively

low temperature because of the contribution of their anti-bonding chemical bond nature.

Fe, Co and Fe0.7Co0.3 were sputter deposited with Al in nitrogen

atmosphere to improve the thermal stability of their nitride thin films. Their respective

mixture with AlN was obtained by the post annealing of the cosputtered nitride thin films.

Nanostructure effects are now being investigated to improve their magnetoresistivity of about 1%.

3. Future view

Nanostrucure needs to be controlled intensively to obtain high performance of the

functional materials. Post annealing has been done by the sample heating in furnace.

We have started to study laser heating effect to precipitate the metal dots in ordered way.

Size and shape control of e-Fe2O3 particle will

also be interesting in its precipitation from silica matrix and also in inverse micelle.

4. Publications

- Y.Kawaai, A.Yamada, T.Takeda and S.Kikkawa, Preparation and magnetotransport properties of α-Fe dispersed AlN granular films, Jpn. J. Appl. Phys., 43, 5671-5672(2004).

- S.Kikkawa, K.Kubota and T.Takeda, Particle size dependence in low temperature nitridation reaction for Fe16N2, J. Alloys and Compd., 449(1-2), 7-10 (2008).

- S. Kikkawa, A. Yamada, Y. Masubuchi and T. Takeda, Fine Fe16N2 powder prepared by low-temperature nitridation, Mater. Res. Bull., in press.